PRODUCT GALLERY

we are the manufacturer of air pollution control system & spares. Our aim is to assist Industries to responsibly release the industrial pollutants thereby supporting the environment to achieve sustainable growth. Our Clean air solution addresses the alarming threats these hazardous air pollutants, such as SPM(suspended particulate matter), hazardous gaseous emissions, Volatile Organic compounds(VOCs) & Odours radiates.

Our Products are :-

- Bag Filter System

- Dust Collector Systems - De-Dusting System

- Cartridge Type Bag Filters

- Fumes Extraction System

- Cyclone Separator

- Centrifugal Fan & Blowers

- Filter Bag

- Bag Supporting Cage

- Rotary Air lock valve

- Miscellaneous Spares of Air pollution control systems

Bag Filter System

Pulse Jet Bag Filter System, are used for separation of solids from air/gas or steams. The particles are separated by fabric (Woven & Non –woven ) Filter bags vertically placed within a housing. For preventing collapse under vacuum or pressure, these bags are retained by metal cages fitted with venturies.

Application

These Online/offline Pulse Jet filters are used where air –flow are in large quantity, temperature are higher than ambient or material to be handled is difficult.

Dust Collector Systems - De-Dusting System

Dust generating points inside the plants like belt conveyor transfer points, crusher venting, screen venting etc. is connected to the bag filter inlet by duct work.For Dust Extraction system applications, the no. of points from where the air borne dust is getting generated are provided with suction hoods and manual or motorized dampers in ducting depending upon the application. The dampers are provided for balancing so that optimum suction is obtained at each suction point. These hoods are connected by small duct network to the main duct header which is finally connected to the bag filter.

Basic Benefits

- Reduce employee exposure to dust.

- Comply with health and air emission standards.

- Reduce nuisance and dust exposure to neighbors.

- Recover valuable products from the air.

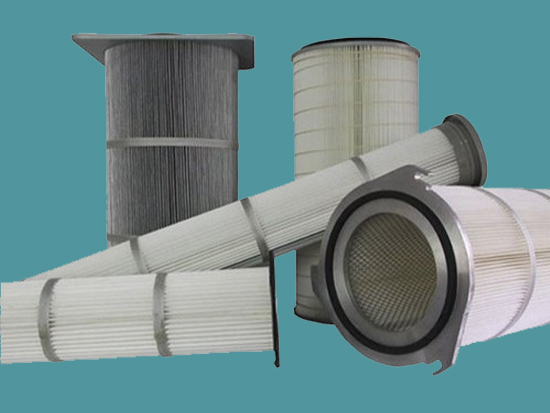

Cartridge Type Bag Filters

Cartridge type bag filter also known as Pleated Type Filters. Cartridge collectors are another commonly used type of dust collector. Unlike bag house collectors in which the filtering media is woven or felt bags, this type of collector employs perforated metal cartridges that contain a pleated, nonwoven filtering media. Due to its pleated design, the total filtering surface area is greater than in a conventional bag of the same diameter, resulting in reduced air to cloth ratio, pressure drop, and overall collector size.

Cartridge collectors are available in continuous duty designs. In the continuous duty design, the cartridges are cleaned by the conventional pulse-jet cleaning system.

Fumes Extraction System

Geo FilTech as leader in Air pollution control, and dust collector system provides, Galvanized plating fume extraction, laser cutting fume extraction, plasma cutting fume extraction Systems.Dust and fume extraction systems to help the different industries and its workers keep safe from the flue gases, and different other pollutants, and fine dust from entering the system of both human and machines. We are believe in protecting and preserving the environment from harmful gases, and keep it safe for the future generations, without affecting the development, and production capacity of the various heavy industries

Cyclone Separator

Cyclone dust collector is the basic conventional mechanical method to separate the heavy dust particles from the air stream using centrifugal cyclonic/vortex effect due to tangential rotation. Industrial cyclone dust collector can be used where particle size of the dust is heavy, as primary separator to reduce the dust load on the fabric filter or dust collector.

By Cyclone Separator we can get maximum efficiency of dust separation with lower power consumption. This has resulted in better outlet emission, lesser load on bag house or bag filter or dust collection system, improving life of filter bags and better recovery of products.

Centrifugal Fan & Blowers

Centrifugal ID Fan or boiler FD fans are the most efficient and versatile pieces of moving equipment. As the prominent industrial fan/blower manufacturers we know that Centrifugal fans are quiet and reliable and are made to operate in a variety of environments and applications.

Manufacturing systems use centrifugal air blower or centrifugal fans to move air, gas, and raw materials through processes across the operation. Centrifugal fans come in a variety and are the most popular choices for today’s modernized air handling applications. They are very simple in design centrifugal fans are manufactured easily and quickly and can save a lot on production costs.

SALIENT FEATURES

- High efficiency robust design

- Impeller with backward curve & backward inclined & radial blades

- Sturdy and heavy duty construction for reliable vibration free/long lasting performance.

- Capacities from 500 m3/hr to 3,00,000 m3 /hr and pressure up to 120 mbar

- High fan efficiency and relatively low noise levels.

- Blade shape is conducive to material buildup

- Drive arrangements: Electric motor is the power source of fans. For larger units, the motor is coupled directly to the fan or indirectly by a belt drive, unlike packaged fans

- Performance tested as per relevant IS standards in the factory “performance test rig”

- Available in spark-proof construction.

- VFD Arrangement as per application suitability.

- Flow control can be done by inlet dampers.

Filter Bag

we are the manufacturer and exporter of all Kinds of Industrial Filter Bags. Geo FilTech is a established manufacturing and exporting field and serving in large and small scale Industries since from last 11 years In Gujarat, Chhattisgarh

& Kolkata States.Ccurrently we have started our new manufacturing plant is Bhopal (Madhay Pradesh). we understand the reliability of a product, plays a vital role in the field of Dust collector filter bags , Tested products from top ranking manufacturers. Geo FilTech is really reliable for everything in filter bags under one roof.

Our Fabric media for Filtration are -

- Non Woven Filter Bag.

- Fiber Glass Filter Bag – A. -Fiber Glass Filter Bag with PTFE membrane. B. -SGT Fiber Glass Filter Bag. C.-Woven Fiber Glass Filter Bag.

- PTFE Filter Bag

- PPS Filter Bag

- Homopolymer Acrylic Filter Bag

- Polyester Filter Bag

- Anti-Static Filter Bag

- Ryton Filter Bag

- P84 Filter Bag

- Cement Plant Filter Bag

- Cartridge Type Filters.

Cartridge Filter-

Bag Supporting Cage

We manufactures filter bag cages of all type air pollution control systems. we have semi-automatic machinery set up for all type cages manufacturing., QA/QC procedures. We provide a wide range of configurations to best fulfill your needs. Cages are produced in a variety of metals, coatings and techniques. Our objective is to provide a fully integrated design, manufacture supply filter of filter Bag Supporting Cages.

| Sr No. | Type | Vertical Wire | Horizontal wire | Finish | MOC/wire Dia. |

|---|---|---|---|---|---|

| 1. | Snap Band Top/Bottom Closed. | 8,10,12,14,16,18 | Ring Spacing 100-120mm | Galvanized plating/HR aluminum finish | MS 2062Gr A./SS304/SS316/Ø3, 3.5, 4,5mm |

| 2. | Collar Type Top/Bottom Closed. | 8,10,12,14,16,18 | Ring Spacing 100-120mm | Galvanized plating/HR aluminum finish | MS 2062Gr A./SS304/SS316/Ø3, 3.5, 4,5mm |

| 3. | Split Joint/Hook-Lock arrangement | 8,10,12,14,16,18 | Ring Spacing 100-120mm | Galvanized plating/HR aluminum finish | MS 2062Gr A./SS304/SS316/Ø3, 3.5, 4,5mm |

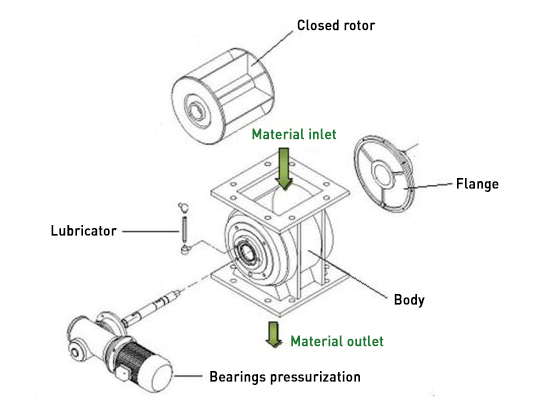

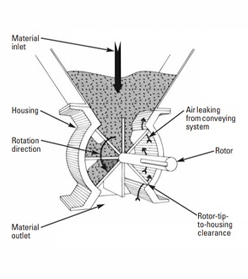

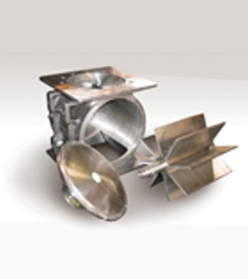

Rotary Air lock valve

Geo filtech is leading manufacturer of RALV, Our valves are designed to handle high-volume dust loads, these rotary valves help to enhance air quality and keep your machinery clean.

Main Features of Rotary Air Lock Valve :

- It has housing , end covers and Casted or fabricated rotor

- Housing and end cover can be made of cast iron, stainless steel as per requirement.

- For special purpose replaceable blades type rotor design is available

- Antifriction outboard bearings.

- Air purging arrangement through end cover available as special feature.

Salient Features of Rotary Air Lock Valve :

- Precision Construction

- Casted Body

- Multi vane Rotor (with adjustable tips / Beveled tips)

- Sealed outboard bearings

- Optional venting & purging

- Packing Glands

- Self lubricating bearing

- Fall through Type/ Blow through Type.

- Pallet type Rotary Air lock valves designed for handling Plastic Granules to avoid jamming

- Powder Design for handling Powder

- Used for High temperature Application

- MOC: MS 2062Gr A. / SS304 / SS316

Application of Rotary Air Lock Valve

- Chemicals Industries.

- Petrochemicals Industries.

- Pharmaceutical Industries.

- Paint & Pigment Handling Industries.

- Food Industry Industries.

- Power Industries.

- Industries.

- Cement Industries

- Mineral Processing Industries.

Miscellaneous Spares of Air pollution control systems

We are the supplier of all spares used in Air pollution control systems.

A.

Pulse Valve - we are the supplier of all type pulse valve like as1” – 25NB. 1.5” - 40NB. 2”- 50NB.

- Available Make Ready Stock – 100Nos.All.

- ASCO Make.

- Manik make.

- Rotex make.

B.

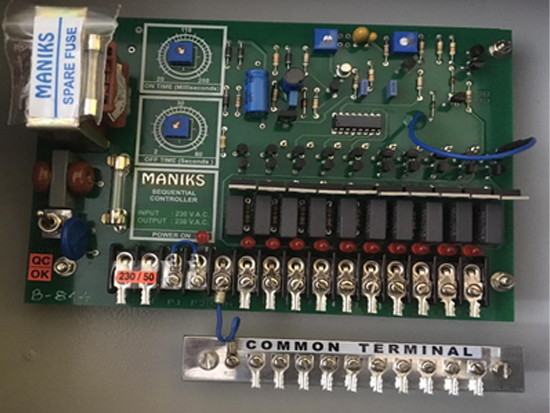

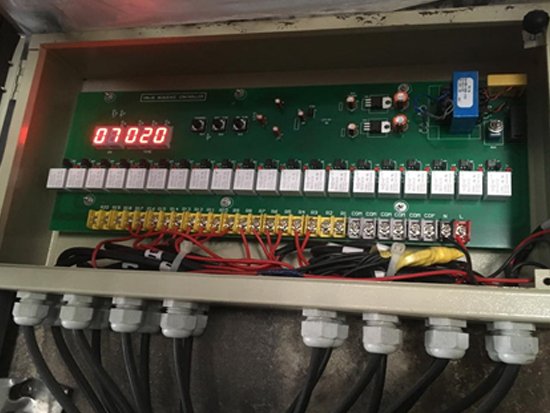

B. Sequential Timmer - we are the supplier of all type for valve pulsing application. like asCH – 8, CH – 10,CH – 18….

- Available Make Ready Stock – 100Nos.All.

- Manik make

- Geo Filtech make